Multi-segment linear axes with excess length

Linear axes are used in a lot of industries. For example, they are used to transport components inside and outside a system or to position them accurately in a machine for the next processing steps.

Depending on the field of application and the respective task within the process, different designs of linear units are available. Therefore, the standard product range offered by Bahr Modultechnik comprises axes with belt drive, spindle drive, toothed rack drive or linear motor drive as well as non-driven linear axes. Uniform connecting elements enable customers to combine the advantages of the individual axis types in a gantry system with one, two or more axes.

Linear axes longer than 6 metres? No problem with our connection systems.

Bahr Modultechnik offers its customers individual section lengths of up to 6000 mm and multi-segment units with lengths of over 24000 mm for all linear types, except for linear units with spindle drive. This is unique and sets us apart from the competition. The modular design makes it easy to design and implement economical and custom-fit system solutions. Below we would like to present to you the butt joint systems of multi-segment linear axes with excess length (> 6 metres) based on our product series.

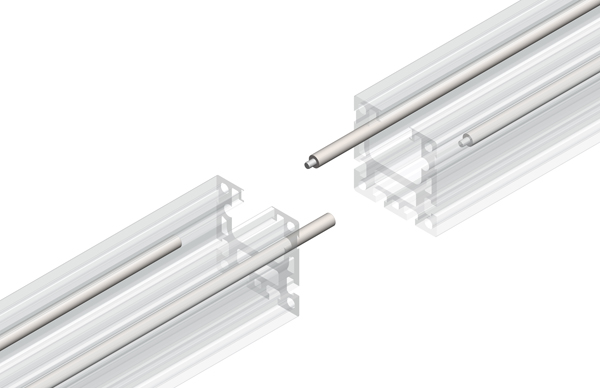

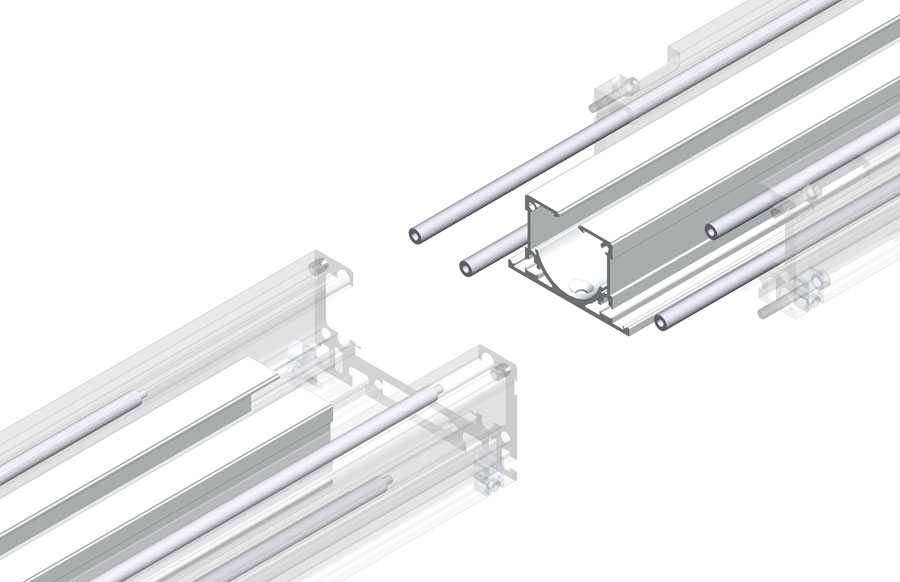

Multi-segment linear axes with guide shafts

The positive locking guide shafts of the EL series are arranged in parallel on the outer sides of the aluminium square profile and are mounted offset to one another to ensure high stability. With the help of mounting brackets, which are used for mounting and extending linear units, the stability within the positioning system can be additionally increased. The fixation is typically achieved by means of through holes and threaded holes on the supporting bracket.

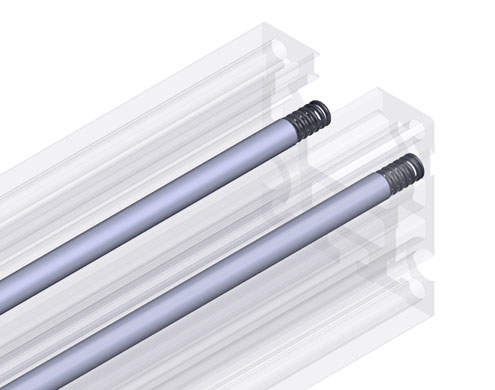

Compensation of temperature variations

Due to its internal belt guide, the ML series differs from the EL series only in its aluminium profile shape and thus in the changed geometries of the belt reverse unit. The technical function principles of the two product series are identical.

The LL and QL series also hardly differ from the EL and ML series in terms of their connection system. The guide bodies consist of an aluminium square profile. Two parallel internal guide shafts are offset to each other to guarantee perfect profile stability. Connecting profiles are used to ensure additional stability for extended linear units.

In order to compensate for temperature variations, springs are mounted in the reversing units at both ends of the linear axis to compensate for the different expansion coefficients of the guide shafts.

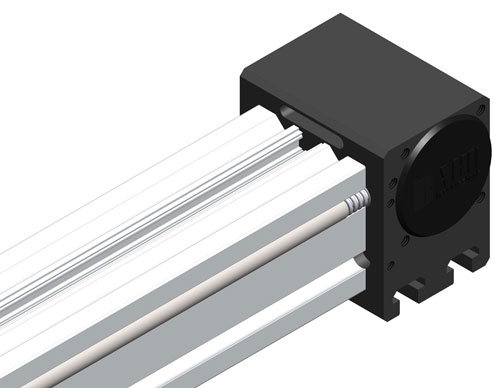

Multi-segment linear axes with guide rail

The guide bodies of the QS and LS series consist of an aluminium square profile with an integrated internal rail guide. The guide rails are offset and thus ensure perfect profile stability in the butt joint. Connecting profiles are used on the support bracket to achieve additional stability and to support extended linear units.

In the DS series, millings for extending the linear axis are provided and incorporated directly into the aluminium rectangular profile, instead of using mounting brackets. The split rail guides are butted at several points. To avoid even the smallest possible tolerance deviations, only rails of the same lot are joined together.

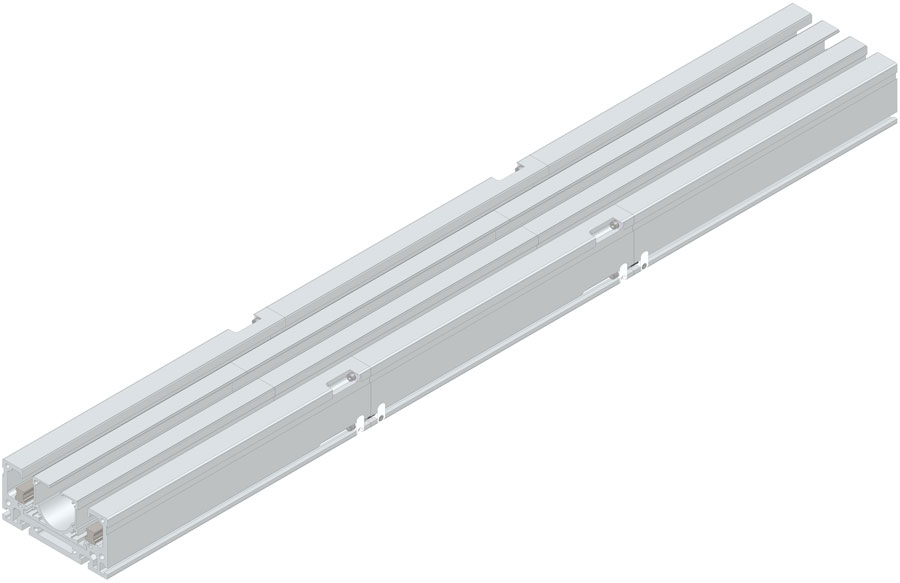

DL series with internal roller guides

The guide body of the DL series consists of an aluminium rectangular profile with two integrated internal roller guides with a total of four guide shafts that are offset to one another. The guide shafts, in combination with the face-milled butt joints, ensure perfect profile stability. Profile screw connections are realised via milled pockets at the respective connection points and provide additional hold.

Any temperature variations that may occur are compensated for by using springs in the mounting flanges on the face sides to counteract expansion of the materials.