LINEAR AXES IN CHEMICAL AND PHARMACEUTICAL PROCESSING

Facilities for the chemical and pharmaceutical industry must meet the highest quality and safety standards over the complete lifecycle. And that’s exactly what we offer. Our linear axes are ATEX-certified for areas of application such as vacuum technology, clean room technology, and explosion protection. Take advantage of our customized solutions of the highest quality and precision.

CHEMICAL & PHARMA

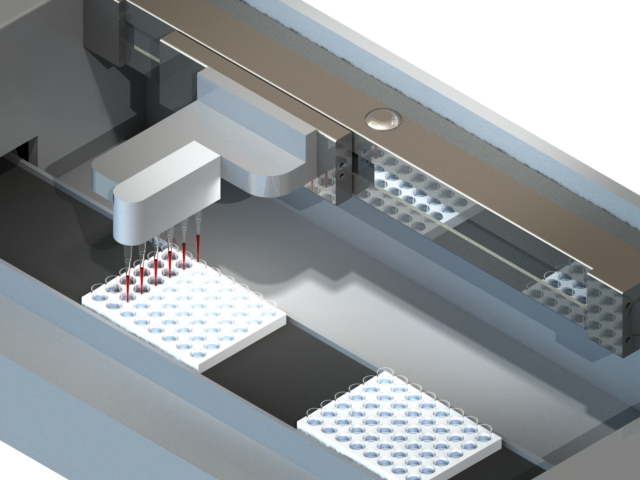

LINEAR DRIVES IN HYGIENE DESIGNS

When pharmacies invest in automated warehouse logistics, the process usually involves modifications to existing premises. As a result, the supply and provision of drugs via an automated picking system is subject to structural restrictions.

System manufacturers of logistics solutions must therefore be able to adapt – and that’s why they use linear axes by Bahr Modultechnik in the positioning technology. The drives can be freely configured in terms of length and function. This individual solution space based on a standardized modular construction kit provides a valuable degree of freedom for using a pharmacy’s available storage capacity to its full extent.

Pharma and chemical manufacturers also benefit from these advantages in the fields of bottling, packaging, and intralogistics – particularly as Bahr Modultechnik also makes this adaptability available with the appropriate certification for use in clean rooms and ATEX zones.

EFFICIENCY COUNTS FROM THE

PHARMACY TO PROCESS TECHNOLOGY

In many cases, the work and logistics zones of pharma and chemical companies are comparable to hygienic dry areas. It is important that the built-in technology can be easily and effectively cleaned. Stainless-steel surfaces are particularly good in this regard. In addition, they protect the technology thanks to their high resistance to aggressive cleaning agents and corrosive chemicals.

Under these operational conditions, the linear drive systems of Bahr Modultechnik impress with plain and closed profile surfaces. The specialists in linear drive axes avoid any geometric forms that make cleaning more difficult. However, the axes can be individually adjusted and integrated in terms of length and function, through to the appropriate stainless-steel casing.

Have a look at our product catalog.

Our advantages – For you

Take advantage of the benefits we offer. You get a comprehensive solution, customized to your needs:

- Unlimited individualization

- High speed and acceleration

- Process reliability

- Maximum precision

- Advice and support with outstanding customer service

- Comprehensive product portfolio in premium quality

- Short delivery times within 2–3 weeks

- Emergency service and delivery within 24 hours

- Easy assembly with extensive accessories

All features at a glance

- Low noise and low maintenance

- High precision

- Long travelling distances

- Speeds up to 8 m/s and acceleration up to 10 m/s²

- Space saving thanks to compact design

- Long service life and high load capacity

- Low weight

- Aluminum profile with hardened and anodized surface

- Unlimited individualization

- Temperature range from -25°C to +85°C

- Resistant to environmental influences (dust or abrasive materials)

- Certified for the fields of explosion protection, vacuum technology and clean room technology

Do you have any questions?

We will be happy to advise you. Simply contact us via our contact form.