The Universal Positioning Modules Of The EL Series Made By BAHR Modultechnik

The 25th anniversary of BAHR Modultechnik is at the same time the 25th birthday of its EL series positioning systems, which have been proven in many ways. Since the first models have been delivered, Bahr stands on the top of technical development with its EL series, one of the most flexible and variable positioning module programmes on the market. “The axes of our very first product family have been writing an uninterrupted story of success for a quarter of a century – and presently there are no indications that this will change,” said Dirk Bahr, Head of Design at Bahr Modultechnik. “Due to their consistently modular design and manifold equipment options, these axes can be used to design very economic, custom-fit solutions for almost any positioning task.”

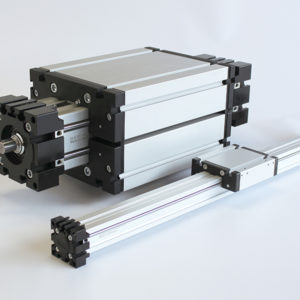

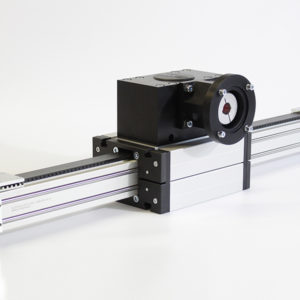

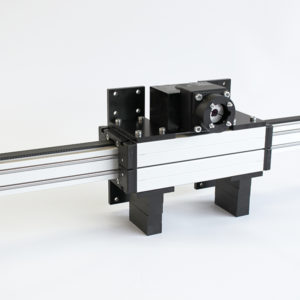

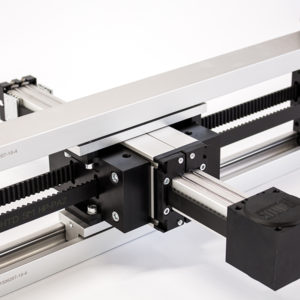

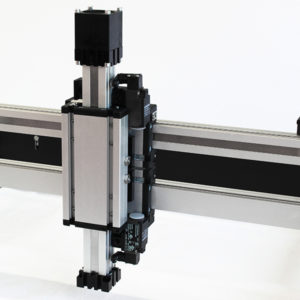

The drive systems for the carriages, which are supported by exterior roller guides, can be chosen from a variety of possibilities, e. g. toothed belt, trapezoidal thread spindle and ballscrew spindle as well as measuring and servo toothed rack. Depending on the drive type, repeating accuracies of up to ± 0.1 mm at travel speeds up to 10 m/sec can be realised. Depending on the type, axes with graduated profile widths of 30, 40, 60, 80,100 and 125 mm are available with freely choosable lengths – the maximum is 60 meters for toothed belt types.

EL axes with profile widths of 60 mm and 80 mm are also offered by BAHR as heavy-load variants with reinforced rollers. In addition, the product series comprises versions with two separately driven carriages, axes with additional drive at the carriage, lifting axes with rotating toothed belts, telescopic toothed belts, area gantries as well as explosion-protected linear units with ATEX certification for use in zone 1 (gas) and zone 22 (dust). Based on BAHR’s proven module principle, nearly any desired combination of the standardised components is possible and can be tailored to customer-specific applications. Motors and controls of all usual makes can be connected to the positioning axes via coupling claws. On request, BAHR performs machining of the axis profiles; we can for example provide bore holes for mounting customer-specific applications.